Celebrating 70 years of Innovation

03

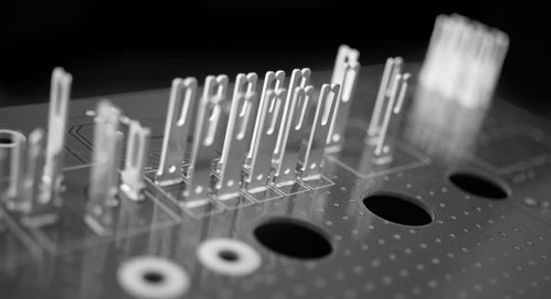

INTERCONNECT ASSEMBLY

Autosplice offers sub-assembly services with PCBA, terminals, and molding to support your specific industry through one supplier. Flex line approach allows flexibility to support volumes that are less attractive to the big box EMS environments. Our interconnect solutions are ideal for high mix, low volume needs, offering turnkey assembly capabilities with built-in quality control at every stage.

+ ENGINEERING

Years of experience in Power Distribution Module design to interconnect assembly development, Autosplice engineering is positioned to support your product design requirements.

-

Mold flow analysis

-

Circuit board design

-

Rapid proto type support

-

Mechanical design

-

Test validation support

+ TERMINATIONS

Many standard terminals in full range of thicknesses for current handling applications .64 mm, .84 mm, and 1.2 mm thick. Blade families are open tooled and able to support your project providing solutions off the self and custom.

-

1.5 mm

-

2.8 mm

-

Tuning forks (sockets)

-

Press-Fit Technology

-

Solder tail

-

Power lug terminations

-

Busbar solutions

+ VERTICAL CAPABILITIES

As a global interconnect company, Autosplice is able to provide vertical solutions through assembly services all as a one-stop-shop service provider to our customers. We have qualified PCB sources that have supported our products for years.

-

Molding insert over molded

-

Precision stamping

-

Assembly (PCBA, Housings)

-

Cable assemblies

-

In-house automation

-

Custom overmolding for

harsh environments and

ruggedized applications

see how it is manufactured

01 / FLEXIBILITY

Flex Manufacturing Lines provide capability for quick change over supporting many assembly scenarios:

-

Double-sided assembly

-

Surface mount

-

Odd form components

-

Press-Fit

-

Terminal insertion equipment (Autosplice Machines)

02 / PROCESS

Autosplice over the years has developed in-house support on many processes required for Interconnect assemblies:

-

In-line conformal coating

-

In-line Presses for lug sub assemblies

-

Pin-in-paste for variety of components

-

Double-sided reflow

-

Heavy copper PCBA processes (up to 12 oz layers)

03 / INSERTION

Part of the vertical solution is off-the-shelf products including Autosplice Insertion systems for over 36 years.

Global platforms currently have over 4,000 active insertion systems in the industry.

-

In-line systems

-

Dual head platforms

-

Insertion force monitoring systems

-

2 to 4 insertions per second

-

Exceeds micro strain PCBA requirements

-

Supports all terminal processes

-

Press-Fit to pin in paste for SMT assemblies

04 / TEST

Autosplice testing capabilities have come from the constant growth in the interconnect assembly segment supporting all requirements to ensure high quality and defect free assemblies.

-

In-circuit test

-

Functional test

-

Hi-Pot in-line and off-line testing

Talk to Santana Lugo

Bring us your vertical challenge and will provide a cost saving solution.